When I started with electronics I worked on an old plastic table which was quite unstable. I saw a kitchen table for half the price – brand new. They dropped the price because one of the legs had few scratches.

It has nice 5cm massive legs from thick sheet steel. It’s 100x80cm and it’s extendable to 130 cm length. It’s quite stable and cost me about 40EUR. Although it’s big I quickly run out of space – I got few more multimeters, a new oscilloscope and I planned to build/buy power supply, function generator and other stuff. So I decided to make a shelf.

Of course I had a look at few benches with shelves but prices start at 400 EUR and they are hard to move – big, heavy, one piece. So I looked for a glued wood but I couldn’t find 130cm length. The only one I found is 2 meters long. It’s 20mm thick. The width (depth) is 30 cm. Ideal for most stuff. I also found a nice 48x24mm lath for the legs – also 2 meters long. At the shop they offered cutting so I didn’t bother cutting them at home. I asked the guy in the shop to cut 4 legs 30 cm each and a shelf plane 130cm by 30cm. I saved the remaining wood for other projects.

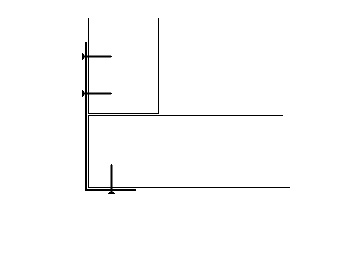

The problem was how to mount it on the table. I didn’t want to ruin the table because it looks nice and I could use it for something else. So I came up with this idea:

I’ve decided to cut a sheet of metal like the letter “L” and screw it at the bottom of the table. That way the top and the sides will stay intact. It was a nice idea, but since I didn’t have a whole bunch of metal pieces at home I struggled to find any metal sheet. And then I saw an old blown PC power supply. I actually have 2-3 of them. So I got my Proxxon FBS 240/E, I put a little cutting fluid and I started cutting:

It took me quite a while – 10-20 minutes to cut one piece … I almost quit when I broke the disk, then I opened a brand new box of dremel disks. I started cutting and 1 minute later I had the second piece:

Then I remembered that the previous cutting disk wasn’t Proxxon. It came bundled with another crappy cheap mini drill which I got for 20 EUR to do dirty work. I’ve easily cut the other 2 pieces.

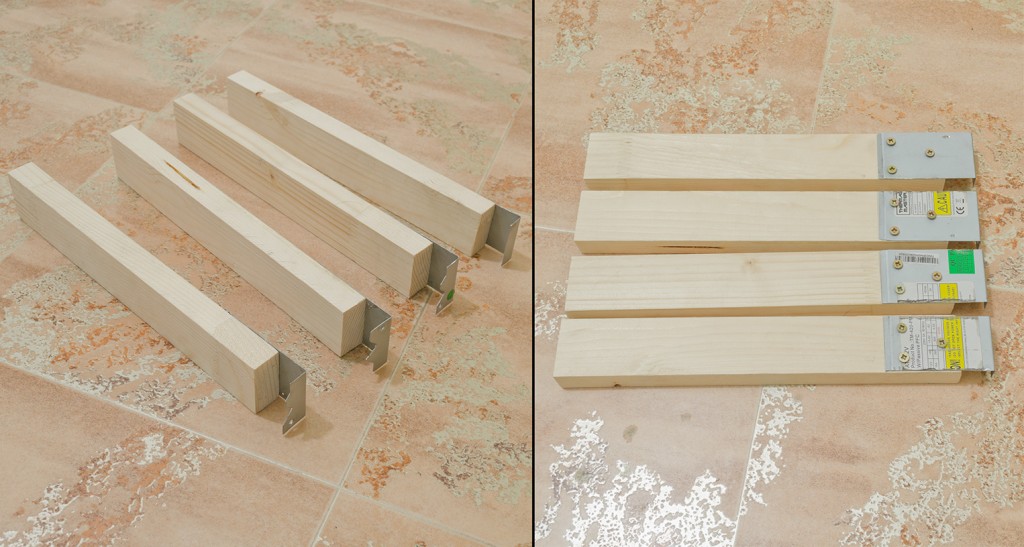

I decided to mount the metal sheets to each leg using 3 screws. This should make them more stable:

I mounted the legs to the plate using 2 big screws (50×5.5 mm lon) for each leg:

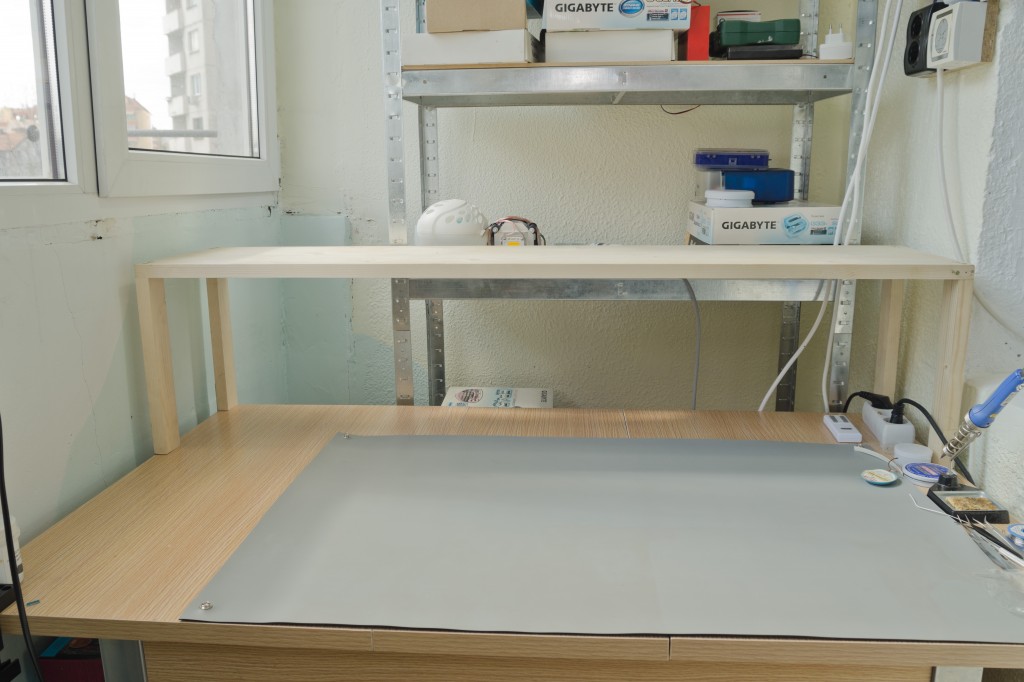

And there it is … upside down because I didn’t want to lay it on the metal brackets:

The metal brackets are pretty thin, but they only have to hold the legs in place. Most of the weight will be handled by the legs itself. My bench/table was in weird corner, so in order to mount the shelf I had to slide it from the front side backwards. Once it got there it was pretty stable even without the bottom screws, but I decided to put them anyway:

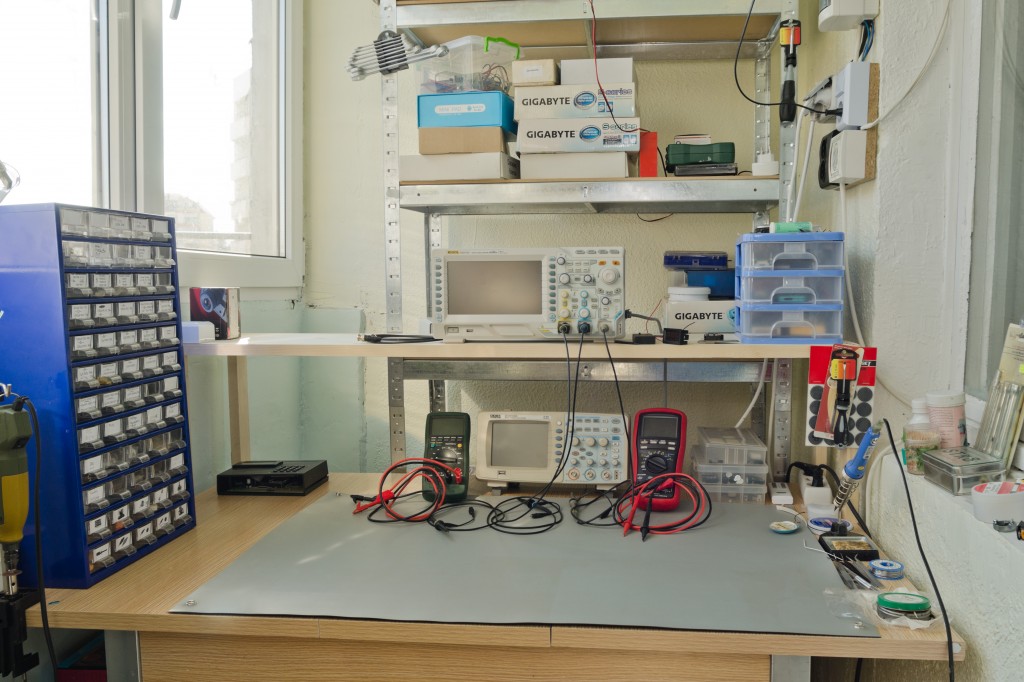

Do you notice how clean my bench is? Yes, every once in a while I try to find a reason to clean my bench. That was a good reason.

Check out how much space I have left for other stuff:

The cool thing is that you can drill holes and hang screwdrivers on it, mount something with screws on the bottom or even cut holes and mount 7 segment led displays on it. It’s wood – easy to cut and drill.

The smell of wood reminds me of my childhood. My grandfather was a woodworker and I used to play around him a lot.

I wonder if I should use some kind of coating for protection at least. I don’t want to use lacquer. I like the way that things don’t slip on it. Maybe some kind of oil. I’m really not into wood working. If someone has a suggestion – drop me a line.

Good luck making your bench shelf!